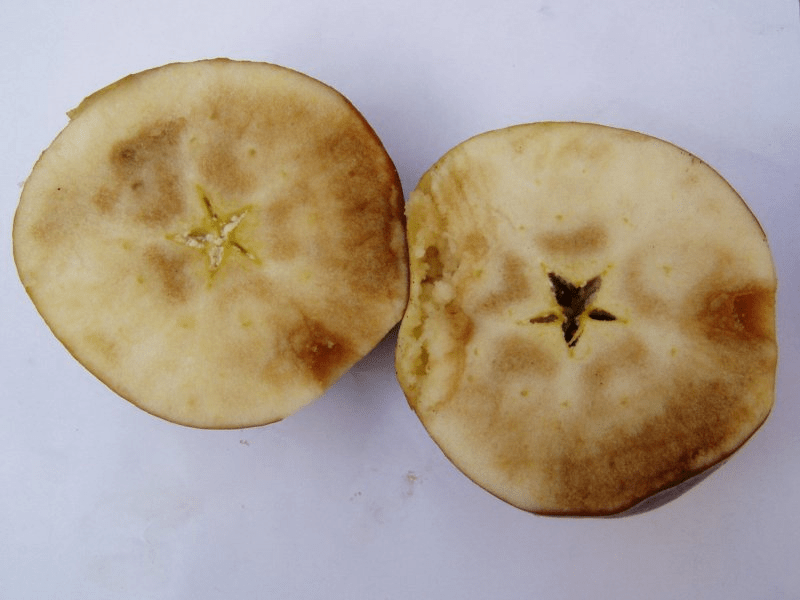

Figure 4. Apple flesh affected by senescent breakdown. Photo: Wageningen Food & Biobased Research.

Preventing Senescent Scald: Key Strategies for Apple Growers

What is senescent scald in apple fruits and what causes it?

Physiological disorders refer to the breakdown of plant tissue or function caused by non- pathological factors. These disorders arise from environmental factors, among others, during pre and postharvest. Other factors including cultivar susceptibility and fruit maturity at harvest also contribute to their development. No matter their origin, physiological disorders greatly affect apples' quality and overall marketability.

Senescent scald in apples is a physiological disorder caused by aging or, in other words, senescence. When apples are overripe, the antioxidative substances in their skin start losing activity and eventually break down in the skin, resulting in a loss of membrane integrity and senescent scalding exacerbated by prolonged storage periods. Because of this natural aging process, apples harvested late and stored for long periods are most susceptible to scald development. Regarding storage, senescent scalding starts developing after 4-5 months in short- term storage conditions and after around a year in long-term conditions.

This disorder is characterized in apples by sharply defined brown patches on the fruit skin that become sunken-in and rough the longer the apple has been kept on the tree or stored (Fig. 1 and Fig. 2).

Senescent scald can develop into the apple flesh as senescent breakdown, resulting in soft, brown flesh underneath the scalded sections of the skin (Fig. 3). Additionally, senescent scald is located predominantly on the sun-exposed side of the fruit. It is important to note that while senescent scald and breakdown share similarities, they are separate disorders. Senescent breakdown differs from scald as it begins under the skin causing internal breakdown and brown, watery flesh (Fig. 4).

What factors cause or contribute to apple senescent scald development?

Multiple factors contribute to apple senescent scald development, such as cultivar susceptibility and fruit maturity. In addition to these factors, preharvest and storage conditions further influence scald development.

A few cultivars, including Golden Delicious, Jonagold, and Idared, are particularly susceptible to developing senescent scald. Golden Delicious (Fig. 2) and Jonagold are more prone to senescent scald because their notably soft, thin skin makes them more sensitive to the breakdown of antioxidant substances that lead to scald.

Senescent scald is closely linked to fruit maturity and aging. The more mature the fruit, or the more delayed the harvest of the fruit occurs, the more susceptible it is to developing senescent scald as the antioxidants in the apple skin break down.

Regarding preharvest factors, apples grown in high nitrogen and low calcium levels are more prone to developing senescent scald. It has been shown that elevated nitrogen and reduced calcium in the fruit increase the incidence and severity of the disorder. Additionally, elevated orchard temperatures have been shown to speed up the ripening process in apples and advance maturity. This can increase the incidence of the disorder, as apples can over-ripen quicker while still on the tree or when in storage.

Furthermore, ethylene-promoter plant growth regulator applications such as Motivate (Ethephon, Fine Americas, United States) during preharvest have been shown to exacerbate the development of senescent scald, with ethephon-treated fruit showing scalding after only six weeks in cold storage. Ethylene is a natural growth hormone that controls much of plant development, including the hastening of fruit ripening. Since senescent scalding is a product of aging, apples exposed to increased levels of ethylene from treatments are more susceptible to developing scalding.

Lastly, postharvest factors such as storage conditions also influence the development of senescent scald. Ethylene exposure and high oxygen levels (>3% in Controlled Atmosphere Storage) can increase susceptibility to senescent scalding as both factors promote ripening and advance maturity. Additionally, apples stored in temperature fluctuation environments are prone to senescence as these large fluctuations in temperature harm the antioxidant abilities and fruit metabolism during storage.

What practices can be implemented to reduce apple senescent scald development?

Multiple strategies have proven effective in preventing or reducing the development of senescent scald.

During preharvest, application of ReTain® (aminoethyl glycine (AVG), Valent BioSciences LLC, United States), which is a plant growth regulator that blocks ethylene synthesis, has shown to help reduce incidences of scalding as it delays ripening. Additionally, foliar sprays of calcium chloride or the application of calcium supplements to the soil also show promise when it comes to preventing senescent scald.

When it comes to maturity at harvest, adequate monitoring of different maturity indices is crucial to ensure apples are not overripe or immature when collected. This careful timing is important for preventing senescent scald as the disorder is heavily reliant on apple maturity and aging. Delayed harvest will increase disorder susceptibility.

Controlling ethylene levels in storage is crucial to reducing scald development. This can be achieved through proper ventilation to maintain air circulation and postharvest treatments that reduce or inhibit ethylene gas production in the apples. Postharvest treatments such as diphenylamine (DPA) dips and applications of SmartFresh™ (1-methylcyclopropene, 1-MCP, AgroFresh, United States) have been found effective in accomplishing this. It should be noted that 1-MCP must be applied timely, as overripe apples treated with 1-MCP showed higher incidences of scalding.

Additionally, ultra-low oxygen storage (ULO) is another effective strategy for managing scald development when paired with ethylene removal processes. It is particularly useful when working with organic apples, as 1-MCP or similar chemical treatments cannot be applied. This type of controlled storage requires reducing oxygen levels to below 1% and ethylene gas levels to below 1 ppm.

Lastly, maintaining consistent cold storage temperatures (32°F or 38°F for chill-sensitive cultivars) is vital to managing the development of senescent scald as the constant temperatures preserve antioxidant capacities and high energy metabolism in apples.

This article is featured in the Vegetable and Fruit News, Vol. 16, Issue 2.

Vegetable and Fruit News is a statewide publication for the commercial vegetable and fruit industries and is published monthly during the growing season (April through October). Subscribers will receive an email with the latest edition.

Subscribe