Controlled Atmosphere Storage of Apples

What is Controlled Atmosphere and why do we use it? To maintain stored fruit quality after harvest, it is essential to understand and control key factors such as genetic background (cultivars/rootstock used), orchard management practices, environmental conditions such as orchard history, and fruit maturity at harvest and postharvest storage conditions. Harvest maturity and postharvest storage conditions are specific for most apple cultivars, so adequate preparation must be taken for each individual cultivar grown under their specific environmental conditions.

Controlled atmosphere (CA) storage is a postharvest management practice based on manipulating the carbon dioxide (CO₂) and oxygen (O₂) concentration in the fruit storage environment, in combination with temperature and humidity in order to maintain the quality and increase the shelf life of stored apple fruits. O₂ and CO₂ are important for storage of almost all fruits and vegetables because they are the two primary gases in fruit respiration.

Apples are constantly undergoing respiration, meaning they intake O₂ and release CO₂ in a similar manner to how humans breathe. Respiration is linked to ripening acceleration, so it is important to slow respiration as much as possible using CA storage, in order to extend fruit storability. If there is a low concentration of O₂ present in the apples’ storage environment, then respiration slows down and fruit quality characteristics are maintained constant or minimal changes take place. As respiration occurs, the concentration of CO₂ in the storage atmosphere will be constantly increasing. A CO₂ -rich environment can also decrease fruit respiration, but in some cultivars, high levels of CO₂ can lead to CO₂ injury, so a regulation of CO₂ concentration is also a target of CA storage.

For most apple cultivars, fruits that are to be stored should be submitted to CA storage as quickly as possible to diminish apple ripening and breakdown. For most cultivars, fruit should be submitted to air-tight storage chambers, and the normal 21% of O₂ concentration of the air should be reduced to 1-3% by flushing the storage room with nitrogen gas.

The CO₂ level of the air in the chamber should also be substantially increased from 0.04% to levels between 0.5-2.5%, depending on cultivar. It is of key importance to maintain a good air circulation in the storage chamber to effectively maintain the gas levels in these ranges. To maintain optimum controlled atmospheres, a gas analyzer should be used to constantly monitor O₂ and CO₂ gas concentrations.

The major advantage of controlled atmosphere storage is increasing the shelf life and marketability of the fruit. It is beneficial to use CA storage on apples that will be stored long-term (4 months or more). The low O₂ environment slows the ripening of the fruit, so fruit from CA storage will reduce its softening rate, and maintain color and nutritional contents. However, CA storage leads to gradual decrease in the fruits’ flavor profile, namely its aroma, when fruits are stored for long periods of time (6 months or more). Another setback is that CA storage conditions can be the development of physiological disorders, which can vary with each cultivar. Storage of a specific cultivar outside of its recommended conditions can lead to further physiological injury, for example, if levels of CO₂ get too high, browning disorders in the skin and flesh of the fruit might occur, rendering the fruit unmarketable. To avoid CO₂ build-up, specialized scrubbers of CO₂ can be used or bags of hydrated lime (calcium carbonate) can be placed inside the room (bags need to be punctured in order for CO₂ absorption).

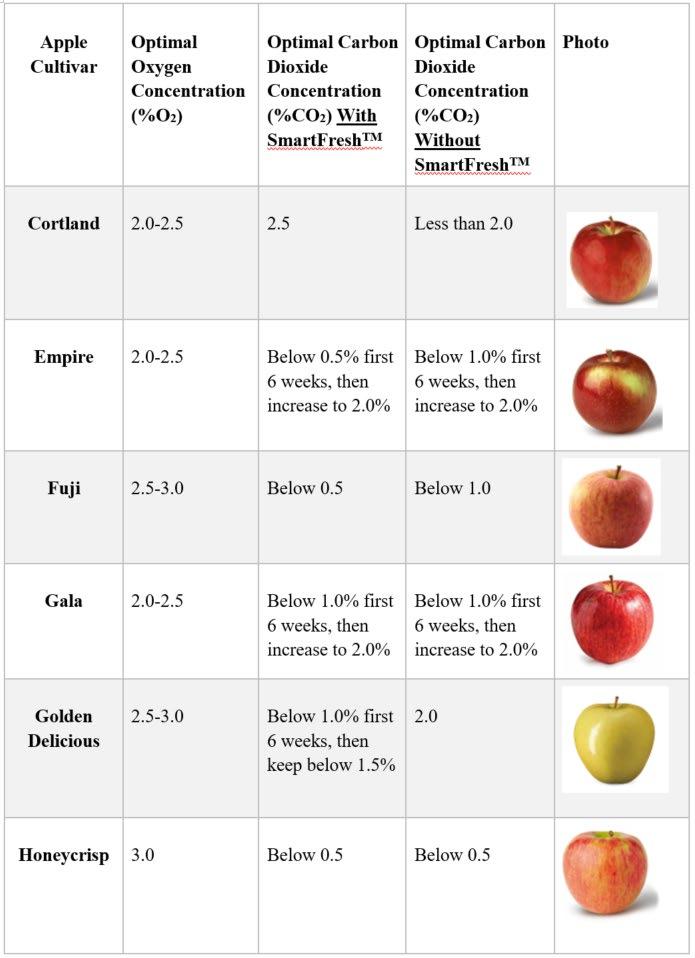

Recommended CA storage conditions for several apple cultivars are shown in Table 1. If storing several cultivars together in the same room, O₂ and CO₂ levels should be adjusted to be suitable for the most sensitive cultivar.

Ethylene is a gaseous plant hormone released by fruits and vegetables during ripening. As apples ripen, they start producing increasing amounts of ethylene which decreases its storability. Ethylene in the environment further triggers its own production, leading to acceleration of ripening in all apples in the storage room.

It is recommended that for storing fruits under CA for more than 6 months, fruit should be harvested at a stage before the onset of ripening known as the pre-climacteric stage, a stage when there is little to no ethylene production. Fruit in the pre-climacteric stage will exhibit higher flesh firmness and starch content, and a background color that has not yet totally turned yellow. It is important to harvest apples bound for CA in this stage so that ripening is not induced on the stored apples.

Because of the acceleration of ripening induced by ethylene, its production and levels should be kept as low as possible while fruits are in CA storage. Ethylene production is strongly correlated with increased respiration of apples. Thus, by managing O₂ and CO₂ levels in CA storage, ethylene induced respiration can be minimized, delaying ripening of the fruit.

Treatments such as application of 1-methylcyclopropane (1-MCP; SmartFreshTM, FysiumTM) can be used in addition to CA storage to inhibit ethylene production. 1-MCP interferes with the fruits’ ethylene perception and delays the ripening process. However, treating fruits with 1-MCP will alter their optimal CA storage conditions, and in many cases increase the sensitivity of apples to CO₂, so it is important to know the cultivar-specific storage conditions with and without chemical treatment. Suggested storage conditions with and without the use of treatments such as SmartFreshTM for different apple cultivars are presented in Table 1.

Fresh apple fruits are perishable products, so it is of producer and consumer interest to maintain apple quality and freshness for as long as possible during storage, and controlled atmosphere storage can play a key role in achieving this purpose if properly used.

This article appears on September 9, 2021, Volume 12, Issue 6 of the Vegetable and Fruit News