Integrating Real-Time Sensing for Smart Irrigation Strategies

Hemendra Kumar, PhD - Precision Agriculture Specialist

Precision Agriculture Lab

Central Maryland Research and Education Center - University of Maryland

Ajay Sengar, Graduate Student - Precision Agriculture Lab

Introduction

More than 40 % of the earth’s population is already experiencing water scarcity problems, and approximately 70 % of available freshwater withdrawal is for meeting irrigation needs in agricultural production to meet food demands. Furthermore, the growing population and ongoing development in the Mid-Atlantic region have significantly increased the demand for freshwater, especially irrigation water requirements, due to recent climatic shifts, including irregular rainfall patterns and rising temperatures during the growing season, which are creating challenges for water availability. With more intermittent rainfall and higher evaporation rates, the risk of short-term droughts during the summer is becoming more prevalent (Boesch, 2008 and Paul et al., 2020). This study emphasizes the importance of efficient water management strategies to mitigate these challenges. By integrating precision irrigation techniques, this study aims to optimize the irrigation schedules and develop the irrigation prescriptions. Any improvements in the current irrigation practices in the Mid-Atlantic can help conserve limited water resources and promote sustainable agriculture. The sensor-based irrigation method has received a lot of attention since this approach provides real-time soil water status (Kumar et al., 2021). In sensor-based irrigation, soil water dynamics in the soil profiles can be explained using knowledge of the soil hydraulic properties (Kumar et al., 2022, 2023).

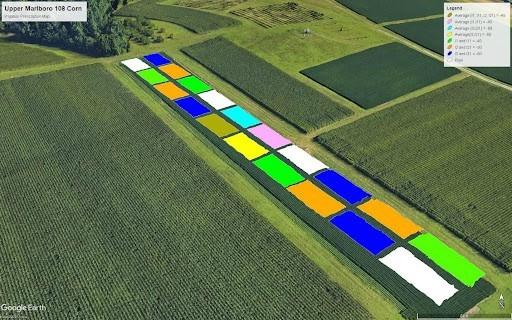

Study area

The study was conducted at the Central Maryland Research and Education Center of the University of Maryland. The corn was planted on June 1, 2024 with a row spacing of 20 inches. Three irrigation treatments and one rainfed scenario (NI) were tested in the field conditions. Each treatment plot was 43 ft long and 43 ft wide. The sensors were installed on June 18 in the field at 6-, 12-, and 24-inches depths. These sensors in each scenario were used to schedule the irrigation at different irrigation thresholds. We estimated the soil hydraulic properties for the study site using the artificial neural network to understand the soil and water engineering for irrigation scheduling. The following were the properties of the soil in this study:

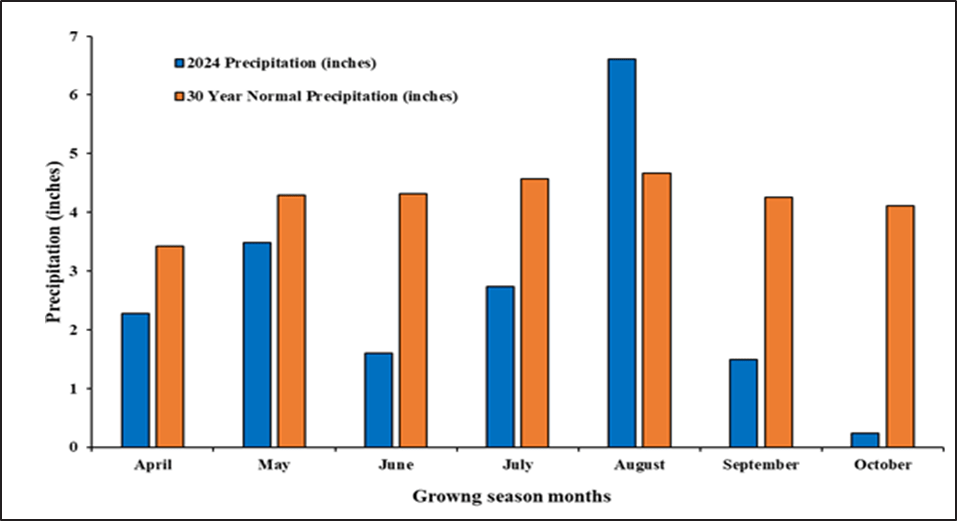

Rainfall variability during the growing season

Based on the 30-year normal precipitation records during the growing season, the 2024 growing season received a total rainfall of 21.3 inches, which is less than the 30-year normal precipitation of 29.6 inches (Figure 4). The precipitation pattern varied throughout the growing season. While the precipitation in the 2024 growing season for all the months received deficit rainfall compared to 30-year normal rainfall, however, August 2024 received excess rainfall compared to 30 years normal rainfall. The total monthly rainfall varies from 0.24 inches to 6.6 inches.

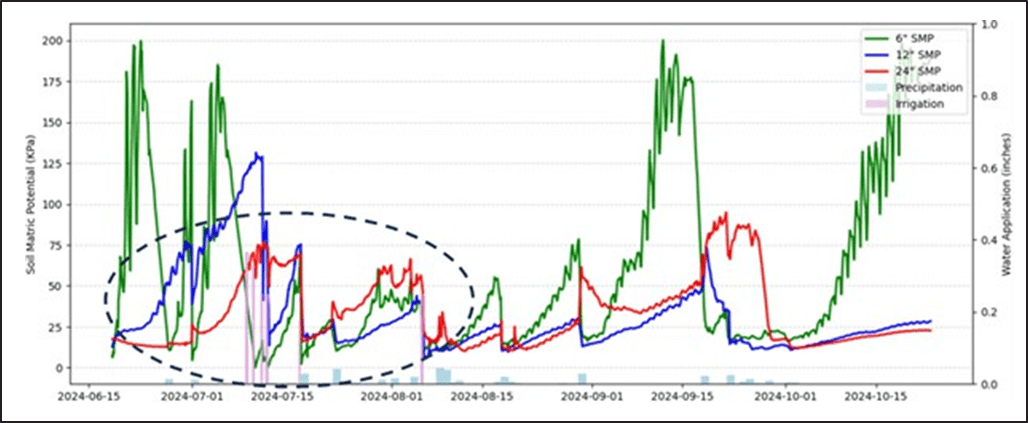

Irrigation Scheduling using soil moisture sensors

Soil moisture sensors were installed at three depths (6”,12” and 24”) with hourly granularity. Rising soil matric potential (SMP) values indicated decreasing soil moisture content and drier soil, while declining values reflected wetter soil, which were often observed after precipitation or irrigation events. Irrigation events were triggered when plot-specific SMP thresholds were reached. Irrigation scheduling occurred using SMP data measured in real time during the growing season in different treatments. I1 and I2 treatments received a total of six irrigations, and I3 received four irrigations during the growing season.

Some SMP patterns observed accelerated soil drying during the summer months of June to August and then enhanced moisture retention during the winter months with a plateauing SMP and minimal fluctuations. Additionally, there was a depth-dependent response with the surface layer (6") showing high variability and the deeper layer (24”) showing the least variability in SMP values. Following this, we used an irrigation prescription frame work where irrigation was scheduled when precipitation was expected to be insufficient to maintain soil moisture levels to prevent irrigation prescription. The idea of the irrigation prescription was to maintain the plant available water in the root zone to meet the crop water demand during the growing season.

Crop growth and yield

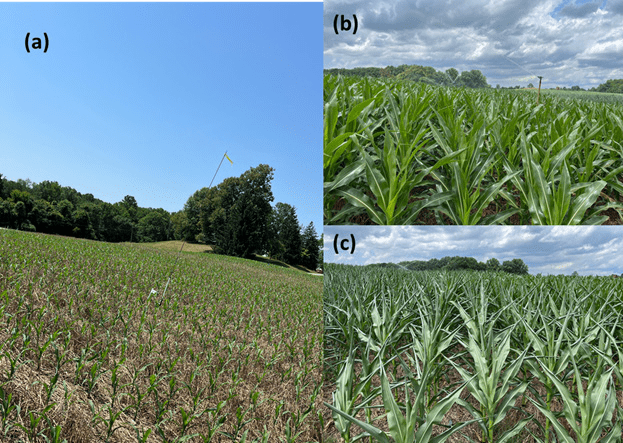

Irrigation plays a crucial role in corn growth, significantly impacting yield, plant height, and overall development. Adequate irrigation ensures consistent soil moisture, promoting optimal nutrient uptake, photosynthesis, and kernel formation. Well-irrigated corn exhibits uniform growth, higher biomass production, and increased resistance to drought stress. In contrast, non-irrigated corn relies solely on rainfall, making it vulnerable to water deficits, especially during critical growth stages such as silking and grain filling. Prolonged drought stress in non-irrigated fields can lead to stunted growth, reduced pollination success, and lower yields. Therefore, proper irrigation management is essential to maximizing corn productivity and maintaining crop health under varying climate conditions. At the silking growth stage of corn in July 2024, irrigated corn had a plant height of 95 inches, and non-irrigated corn had a plant height of 83 inches. The treatment I2 received the maximum irrigation amounts during the growing season, which aligns with the corn yield and pant height data. An optimal water application through irrigation supported growth and development in corn plants, contributing to increased plant height. In contrast, water stress, frequently observed in non-irrigated corn, hindered growth, resulting in stunted development and reduced plant height.

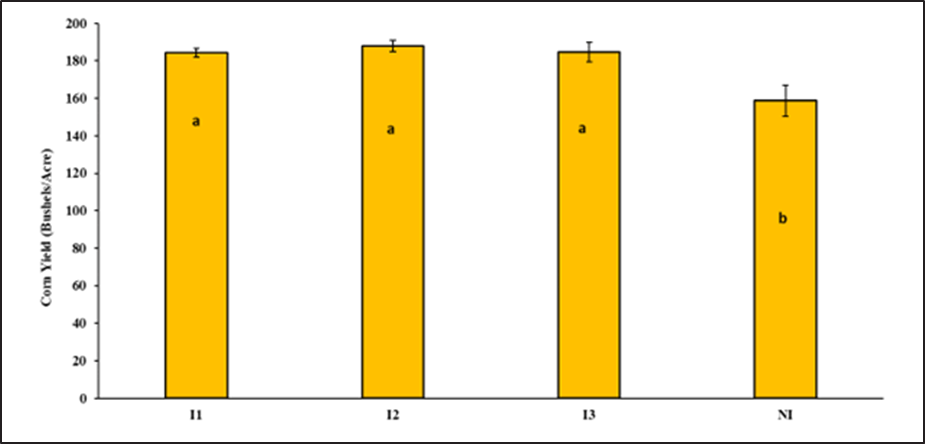

Irrigation had a notable impact on corn yield, as observed across different irrigation scenarios. The treatments I1, I2, and I3, which represent varying levels of irrigation, did not exhibit statistically significant differences in yield, indicating that all three irrigation levels provided sufficient moisture to support optimal crop production. However, the non-irrigated (NI) treatment, while not significantly different from the irrigated treatments, demonstrated a noticeable reduction in yield. The recorded yields for I1, I2, I3, and NI were 184, 187, 184, and 158 bushels per acre, respectively (Figure 5). The yield decline in the NI treatment suggests that while rainfall may have provided some moisture, it was not consistently adequate to maximize corn productivity. These results highlight the importance of irrigation in improving crop yield. This indicates the site-specific need for precision irrigation management due to variable weather extremes.

Conclusion

This study highlights the importance of precision irrigation in optimizing water use and improving corn growth and yield. Real-time soil moisture sensors enabled efficient irrigation scheduling, reducing water stress and ensuring adequate moisture availability. Irrigated treatments resulted in greater plant height and higher yields compared to non-irrigated corn, demonstrating the benefits of targeted water management. Seasonal and depth-dependent variations in soil moisture emphasize the need for site-specific irrigation strategies. Overall, sensor-based irrigation enhances water efficiency, supports sustainable agriculture, and mitigates the impact of climate variability.

Acknowledgment

The author extend sincere gratitude to the Facility Manager (Donald Murphy) and his dedicated team for their exceptional support in conducting this study.

References

Boesch, D. F. (2008). Comprehensive Assessment of Climate Change Impacts in Maryland. Report to the Maryland Commission on Climate Change; Maryland Department of the Environment: Baltimore, MD, USA.

Kumar, H., Srivastava, P., Ortiz, B.V., Morata, G., Takhellambam, ;B.S., Lamba, J. and Bondesan, L., 2021. Field-scale spatial and temporal soil water variability in irrigated croplands. Transactions of the ASABE, 64(4), pp.1277-1294.

Kumar, H., Srivastava, P., Lamba, J., Diamantopoulos, E., Ortiz, B., Morata, G., Takhellambam, B. and Bondesan, L., 2022. Site-specific irrigation scheduling using one-layer soil hydraulic properties and inverse modeling. Agricultural Water Management, 273, p.107877.

Kumar, H., Srivastava P., Lamba, J., Lena B., Diamantopoulos, E., Ortiz, B., Takhellambam, B., Morata, G. and Bondesan, L., 2023. A methodology to optimize site-specific field capacity and irrigation thresholds. Agricultural Water Management, 286, p.108385.

Paul M.Dangol, S. Kholodovsky, V. Sapkota, A. R., Negahban-Azar, M., & Lansing, S. (2020). Azar, M., & Lansing, S. 2020). Modeling the Impacts of Climate Change on Crop Yield and Irrigation in the Monocacy River Watershed, USA. Climate, 8(12), 139.