In today’s commercial poultry industry, dry stack litter sheds are important components of a waste management program. When litter is periodically removed from poultry houses, it must be handled in an environmentally sound manner. To obtain the most value from poultry litter, producers store it until the appropriate application time for ideal plant nutrient uptake and reduced environmental impact (Nottingham, 2012). Therefore, a litter storage structure becomes critical to a poultry operation’s nutrient management program. When properly managed, a storage facility protects litter from the elements, preserves nutrients in the litter, lessens the threat of runoff and water pollution, and allows for proper timing of land application to meet crop and forage needs.

Fire Danger

Producers should be aware, however, of the fire danger associated with storing poultry litter (Figure 1). As microbial activity occurs within the litter, heat and methane gas are produced. Heat is also produced at the boundary layer between moist and dry litter in the storage pile. Spontaneous combustion (self-ignition) in a litter pile can occur from this buildup of heat and methane. Fires may also occur if litter is stacked too closely to the wooden walls of the shed, which can ignite if the temperature in the litter reaches the wood’s flash point. The process is similar to spontaneous combustion of hay bales or silage stored in barns or silos, respectively. However, less is known about spontaneous combustion of litter. Additionally, it is important not to drive a tractor on stored litter as this can compact the litter and increase the likelihood of a fire (Figure 2).

We have known for some time that heat is generated when microbial activity occurs in an insulated environment, such as a garden compost pile or dairy manure stored outside. Overheating and spontaneous combustion in hay barns, coal piles, landfills, and containers of oily rags are not uncommon occurrences. Both biological and chemical factors are likely associated with litter storage fires, although the exact causes are not well understood.

Fires and explosions have occurred before in sanitary landfills that generate combustible methane. For methane to be generated, conditions must be right for the growth of anaerobic bacteria. This includes proper moisture content (greater than 40 percent) and an oxygen-free or very-low-oxygen environment. Methane has a specific gravity less than air and, therefore, can escape to the atmosphere given a proper conduit (i.e., adequate pore space in the surrounding litter). However, litter that is compacted and insulated in a storage shed may not have adequate pore space.

Methane is flammable in air at concentrations of 5 to 15 percent. As such, production of methane in litter storage is a potential fire hazard. If the pile is compacted and insulated by additional litter being placed on top of compacted litter, overheating and spontaneous combustion may occur as temperatures rise above 190°F. While microbial activity may generate much of the heat, it is likely chemical reactions that cause the fire. Because most bacteria are killed between 130°F and 165°F, chemical reactions are most likely responsible for the processes that lead to the actual combustion.

Common Risk Factors

There are several common factors that are usually present when a litter storage shed fire occurs:

-

Moisture. Moisture is a critical factor in all litter storage shed fires. Dry litter does not generate heat well, but wet litter does. Perhaps the most common mistake made by producers is adding moist litter to dry litter already in the shed. A second mistake is allowing wind-driven rain to reach the litter stored in the shed. The layering effect that occurs when new, moist litter contacts old, dry litter creates an insulated heat- and methane-producing area as the dry litter absorbs moisture. Anaerobic bacteria generate about 50 to 65 percent methane, about 30 percent carbon dioxide, and a smaller percentage of other gases (Hess et al., 2018). If the moisture content of stored litter is more than about 40 percent in a pile with little or no oxygen, anaerobic bacteria will grow and produce methane gas. Litter added to the pile at less than 40 percent moisture will lessen the risk of heating and methane production. If the pile is not compacted and has adequate pore space, any methane that is produced can escape into the atmosphere and will not concentrate in the pile.

-

Pile size. Pile size will affect heat release. Height and width are more important than length of the pile. The larger the pile size, the greater the chance for excessive heat and fire. Small piles provide a larger surface area for heat release. Litter in the shed should not be stacked more than 7 feet high at the center of the pile.

-

Compaction. Compacting litter encourages anaerobic conditions. Compacting traps heat in the pile and lessens the available pore space for dissipating heat and methane.

-

Layering. Layering new, moist litter on top of old, dry litter creates a dangerous, heat-producing situation. Only dry litter should be added to litter already in the shed.

-

Caked litter. Caked litter is often wet litter with a high moisture content and can increase the risk of litter storage fires. It is best to separate caked litter from dry litter in the shed until the caked litter has dried.

Best Management Practices

-

Dry litter is best to lessen the fire danger. Protect litter in the shed from blowing rain. Do not add wet litter to dry.

-

Do not compact wet or dry litter as this encourages anaerobic conditions and increased heat and methane production.

-

Do not stack litter over 7 feet high.

-

Store wet, caked litter in a separate area from dry litter.

-

Stack litter away from wooden walls and support posts, to the degree possible.

-

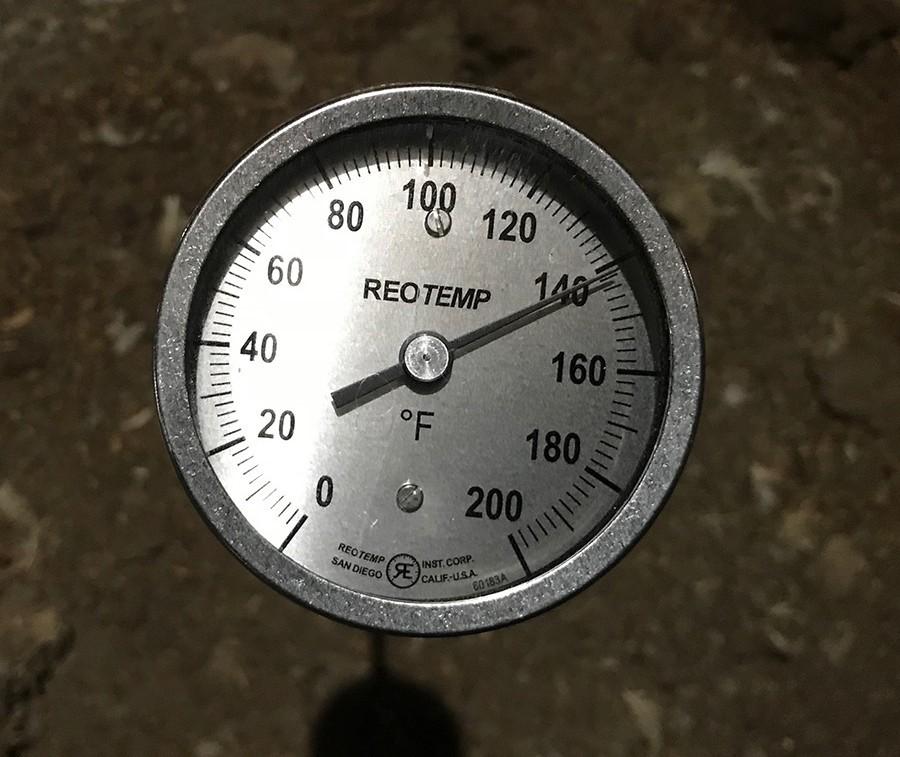

Monitor temperatures at various locations within the pile on a regular basis with a 36-inch compost thermometer (Figure 3). Temperatures of 160°F or less are normal. Temperatures above 160°F are an indication that closer attention and caution are needed. Remove any materials that have a temperature greater than 180°F. If temperatures are 190°F or greater, or if the pile is smoldering, notify the local fire department and get instructions on safely removing the material from the storage shed. Use extreme caution when digging into the pile because a smoldering pile can burst into flame when exposed to oxygen. Be aware that a garden hose is not adequate fire suppression equipment if a litter pile bursts into flame. Spread the litter on a field using caution to avoid catching dry grass or other combustible materials in the field on fire.

-

Do not store expensive farming equipment such as tractors, combines, decaking machines, windrowing equipment, hay mowers, rakes, and balers under the litter storage shed.

Summary

Litter storage sheds are a vital part of every broiler operation’s nutrient management program. Litter storage allows flexibility in timing land applications and lessens the possibility of polluting surface and ground waters, as could occur with litter stored outdoors. Litter storage shed fires are possible because of heat and methane buildup in litter stacked in the shed. Spontaneous combustion in a litter pile can occur under the right conditions. Several common factors can lead to spontaneous combustion in a litter pile. The most critical of these factors is likely litter moisture content; however, pile size, caked litter, layering, and compacting the pile are also important. Proper precautions will greatly reduce the risk of a litter shed fire. Good management and common sense will help keep your litter shed intact and working for you for many years to come.

References

Hess, J. B., J. O. Donald, and J. P. Brake. 2018. Preventing fires in litter storage structures. Alabama Cooperative Extension Service Publ. No. ANR-0915.

Nottingham, R. 2012. Preventing fires in manure storage structures. University of Maryland Extension. Commercial Poultry Newsletter, 1(1):3.

Mississippi State University Extension, Publication 3718 (POD-10-21)

By Tom Tabler, PhD, Extension Professor, Poultry Science; Jonathan R. Moyle, PhD, Extension Poultry Specialist, University of Maryland Extension;

Jessica Wells, PhD, Assistant Clinical/Extension Professor, Poultry Science; and Jonathan Moon, Poultry Operations Coordinator, Poultry Science.