FS-1172 | June 2021

Industrial Hemp Production in Maryland: Frequently Answered Questions

Industrial hemp production has been legal in Maryland since 2018, first through the Maryland Hemp Research Pilot Program and now through the Maryland Hemp Farming Program. This factsheet presents questions frequently asked of University of Maryland Extension (UME) faculty by new growers of industrial hemp.

Due to the novelty of industrial hemp production in the United States, production regulations and recommendations change often. Contact the Maryland Department of Agriculture (MDA) and UME faculty for the latest information. This publication will answer general industrial hemp production questions and will be updated as new information is available. Updated information and additional Frequently Answered Questions can be found at https://extension.umd.edu/programs/agriculture-food-systems/program-areas/fruit-vegetable-production/alternative-crops/industrial-hemp.

Question 1: What is the difference between marijuana and industrial hemp?

Marijuana and industrial hemp are both Cannabis sativa plants and look identical. The difference is related to the concentration of delta-9 tetrahydrocannabinol or delta-9 THC, the psychoactive chemical which the plant produces. This phytochemical is responsible for the impairment associated with the use of marijuana.

Industrial hemp contains less than 0.3% delta-9 THC on a dry-weight basis. Federal and state regulations require analysis of industrial hemp plants for THC concentration prior to harvest and transportation to certify the plant is industrial hemp and not marijuana. Federal regulations currently restrict the production, transportation, and sale of marijuana.

Question 2: I am a new grower and I want to grow hemp. I understand I need a permit to produce hemp. How do I obtain one?

The MDA is responsible for providing permits to hemp producers and registering locations where hemp is produced. You can find Maryland regulatory information, including a copy of the permit application, on the MDA industrial hemp website (https://mda.maryland.gov/plants-pests/Pages/Industrial-Hemp.aspx).

Maryland hemp producers currently have two options: either the Research Pilot Program (ending after 2021) or the Hemp Farming Program. MDA has compared the requirements of both programs in a guide for producers in selecting which works best for their operation, available at https://mda.maryland.gov/plants-pests/Documents/MD-Hemp-Program-2021-Program-Differences.pdf. Producers must obtain a Federal background check before participating in either hemp production program. Information on Federal background checks is available at https://www.fbi.gov/services/cjis/identity-history-summary-checks.

Question 3: Are there loans available to help me get started producing hemp?

There may be limited loan options available to future hemp producers. Financial institutions may find hemp production too similar to federally-illegal marijuana production and therefore, lending is seen as risky. Individual lending institutions must find their comfort level with hemp production and their willingness to lend money to its potential producers.

The Farm Credit Administration has provided guidelines to institutions assessing if individual hemp production operations fit within their lending strategy. The best option for potential growers is to reach out to lending institutions early in the planning process. Discussing lending options well before you need the funds will help you develop your operation’s management plan to ensure compliance with lender guidelines. You can find more information at https://www.dtnpf.com/agriculture/web/ag/blogs/minding-ags-business/blog-post/2020/02/11/financing-hemp-farm-credit-system.

Question 4: I am unsure if I want to grow hemp to produce phytochemicals (CBD, etc.) or to produce grain or fiber. Are there differences in how these different types of hemp are produced?

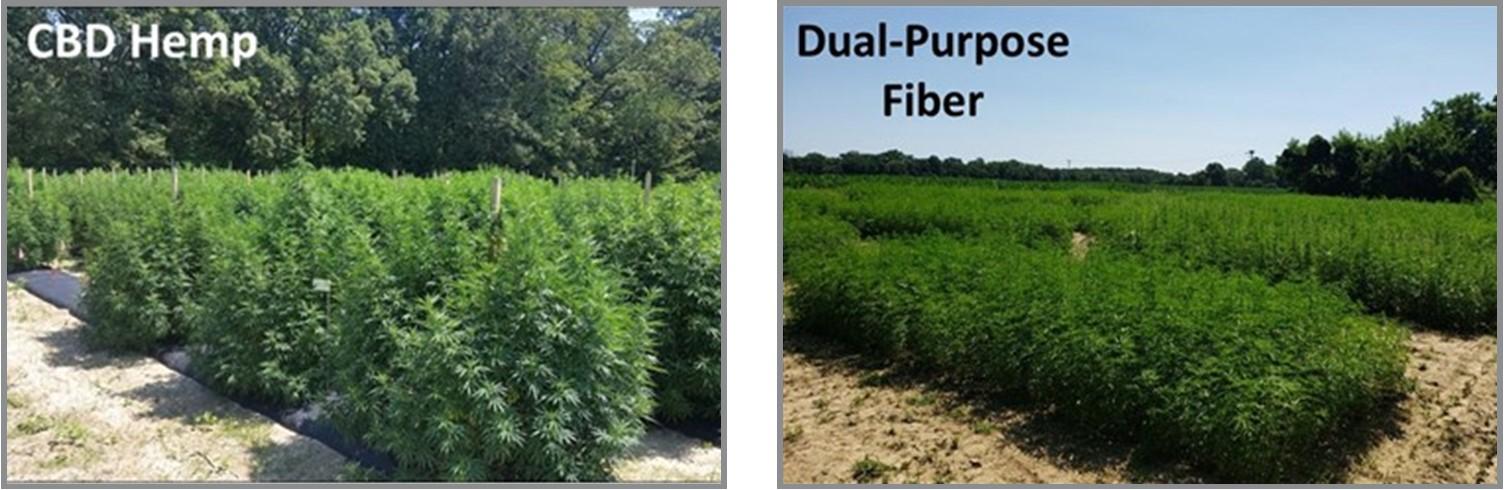

Industrial hemp can be produced with a variety of end-products in mind and the end-product will change the type of hemp grown and how it is produced. You can grow hemp to extract phytochemicals, such as cannabidiol (CBD) from flowers (colas) and leafy biomass. These varieties of hemp, referred to as phytochemical hemp, floral hemp, or CBD hemp, are bred to produce flowers (colas) and biomass material high in phytochemicals. Production is usually similar to high-value crops, such as tomatoes or tobacco, either outdoors or in greenhouses. Outdoor production may include clean tillage, laying irrigation lines and plastic to prevent weed emergence, transplanting plugs, managing in-season weeds, and hand harvesting. Growers use similar care and management in indoor growing environments.

Hemp can also be grown to extract fibrous material from the stalk for industrial production of ropes, clothing, and other uses, or to harvest grain (seed) for use in birdseed or for human consumption (such as hemp seed, pressed oil, etc.). This type of hemp can also be dual-purpose, produced for fiber and grain production, or tri-purpose, produced for fiber, seed, and phytochemical extraction. Fiber-type hemp varieties grow to 10 to 14 feet tall with tough, rigid stalks and minimal flower or leaf material.

Dual-purpose hemp may not grow as tall and will be harvested for seed (grain). Production of dual-purpose or fiber hemp is similar to other agronomic crops. Seeds are planted or drilled into a field, likely tilled to control early season weeds, and harvested with a mower or other equipment to collect grain. Unlike other agronomic crops, there are currently no herbicides approved for weed control in industrial hemp. Quick canopy closure from rapid, early season growth is the best option for controlling weeds in dual-purpose or fiber hemp production systems. Figure 1 shows two different hemp production systems during the growing season.

Question 5: I have heard that hemp is profitable to grow, how much can I make growing hemp?

The University of Maryland collected economic data from local producers who grew CBD hemp in 2019 and 2020. Producers are paid for percent CBD per pound of biomass and this price, like other commodities, fluctuates based on supply and demand. Prior to the harvest of hemp in 2019, producers could receive up to $4 per % CBD per pound of biomass. As the supply of hemp biomass increased, however, the price has dropped to below $0.50 per % CBD per pound.

In 2019, local producers reported yields of approximately 2,000 pounds of dry biomass per acre. Per pound of biomass harvested, producers reported $7 to $14 for input costs (including purchase of plastic, irrigation, and labor), $14 for harvest, and $15 to $20 for processing to CBD. In the following example, we will only consider the input and harvest expenditures prior to processing:

Costs on a per-acre basis of hemp production in 2019:

- $14 per pound input costs (a conservative estimate);

- $14 per pound for harvest labor;

- 2,000 pounds of biomass produced per acre = $56,000 per-acre input and labor costs

Revenue on a per-acre basis, high % CBD, and high price per % CBD in 2019:

- If biomass has 15% CBD and the price is $4 per % CBD;

- 2,000 pounds biomass produced per acre = $120,000 per acre gross revenue

- $120,000 gross revenue - $56,000 costs = $64,000 net revenue per acre

Let’s calculate revenue based on more realistic price of CBD.

Revenue (on a per acre basis), high % CBD, and low price per % CBD:

- If a batch of biomass has 15% CBD and the price is $1 per % CBD,

- 2,000 pounds biomass produced per acre = $30,000 per acre gross revenue

- $30,000 gross revenue - $56,000 costs = $26,000 net loss per acre

At $1 per % CBD, a rather high price for % CBD, a producer is losing over $25,000 per acre. These values better represent the realty of CBD hemp profitability with current CBD prices.

Question 6. Do I need to invest in equipment to produce hemp?

Depending on which type of hemp a producer decides to grow and the size of the operation, investment in equipment may be necessary. CBD hemp production systems, like other high-value crops, require purchase of irrigation lines, a water pump system, and plastic, which may require plastic-laying equipment. Greenhouse production of CBD hemp also has equipment costs associated with irrigation. Fiber and grain hemp production, like agronomic crop production, requires equipment for tillage prior to planting, a drill for planting seed, and mechanical harvesting equipment for harvest of seed or a mower and baler for stalk harvest.

Regardless of the production system and size of the operation, producers should prepare for significant investments in labor force. This is especially true for small- to medium-sized CBD hemp operations because much of the management and harvest of CBD hemp is performed by hand.

Question 7: How do I select the best hemp variety to plant on my operation?

As with any other crop or plant, there will be differences in performance based on the location of the operation. University of Maryland Extension personnel recommend that agronomic producers consult results of variety trials performed within the Mid-Atlantic region to determine the performance of crops. With both agronomic crops and industrial hemp, plant breeding efforts are underway to produce varieties that will proliferate across the diverse U.S. climates. University of Maryland researchers participated in a national dual-purpose hemp variety trial in 2020, where we evaluated 13 dual-purpose (fiber and grain) hemp varieties. We are participating in these trials again in 2021. You can find the results of these trials on the UMD Industrial Hemp website, https://extension.umd.edu/programs/agriculture-food-systems/program-areas/fruit-vegetable-production/alternative-crops/industrial-hemp

While agronomic crop production companies have statewide and regional salespeople to discuss crop varieties with producers, these resources are still developing in the hemp industry. To obtain recommendations for high-performing hemp varieties, producers should reach out to other hemp growers in the state and region. Joining local hemp production advocacy groups can help connect hemp growers across the state.

Question 8: Where do I obtain hemp plants or seeds?

The best way to obtain hemp plants or seed is directly through the company producing the plants or seeds. While other plants and crops can be purchased through a second vendor (think purchasing plants or seeds from a garden center), when purchasing a crop like hemp, growers should ensure they are obtaining a quality product with accompanying documentation to indicate the plants are hemp instead of marijuana. Connecting with local hemp producers to share variety performance recommendations is appropriate; however, obtaining seed from other growers or non-commercial vendors is not recommended. Saving seeds produced on your operation from purchased seed is not legal for patented varieties of agronomic crops. Most legitimate hemp seed companies will not allow redistribution of purchased seed, unless a regional seed dealer serves as a distributor for larger national or international hemp seed companies.

Question 9: Hemp grows like a weed. Do I need to fertilize my hemp crop?

While some feral hemp grows with minimal fertilization, hemp grown to produce high yields and high phytochemical concentration requires the addition of nutrients. Research performed in Maryland in 2019 and 2020 evaluating nitrogen fertilization found that CBD hemp requires about 120 pounds per acre of N to obtain increased yields – similar to what would be necessary to fertilize a wheat crop.

Question 10: Do I need to be concerned about pests or disease in hemp? What are my pest management options?

Cannabis aphid and hemp russet mites are common pests found on transplants of CBD hemp grown in greenhouses. Maintaining good sanitation inside and around the greenhouse will help with management of these pests. Once planted in the field, pest populations on CBD hemp plants are typically controlled by natural enemies and weather conditions. Several species of caterpillars, beetles, grasshoppers, and other insects may appear in CBD hemp fields during the growing season. Most will not do enough feeding damage to require control.

The exception is the corn earworm, Helicoverpa zea, (Lepidoptera: Noctuidae), which is commonly found feeding on the mature hemp flowers at the end of summer. Due to the corn earworm’s tunneling behavior, it is hard to find and control with chemicals. Researchers are conducting experiments on control management tactics and thresholds.

A limited number of chemical control options are approved for industrial hemp in Maryland. Please contact MDA for the most up-to-date list. It is illegal to use non-approved chemicals on a crop. Homemade remedies are not recommended as they may be ineffective and harmful to people, plants, and the environment. You can find additional regional information at: https://www.pubs.ext.vt.edu/content/dam/pubs_ext_vt_edu/ENTO/ento-349/ENTO-349.pdf.

Hemp is susceptible to a number of diseases. Pythium and Fusarium root and stem rots can cause wilting, stunting, and plant death, resulting in significant losses in propagation. Botrytis blight can cause stem cankers and bud blight and there are several fungal pathogens that cause leaf spots on field-grown plants. Different pathogens can induce similar symptoms on infected plants. Pathogens can have different modes of spread, so it is important that growers seek an accurate diagnosis of symptomatic plants. The University of Maryland Plant Diagnostic Laboratory will analyze hemp plant samples. See their website at https://extension.umd.edu/plantdiagnosticlab for more information.

Growers should purchase plants from experienced greenhouse propagators or use good sanitation practices (clean pots and benches, commercial soilless potting mixes) when starting plants from seed or cuttings to avoid disease problems during propagation. When leaves remain wet due to periods of excessive rainfall or overhead irrigation, foliar diseases can develop. Cultural practices such as using drip irrigation and spacing plants to allow for maximum air circulation can promote rapid drying of leaf surfaces and reduce disease incidence. Several biopesticides are labeled for use on hemp to help protect against fungal diseases; a current list is available at: https://www.epa.gov/pesticide-registrQation/pesticide-products-registered-use-hemp. Results from biopesticide applications have varied; however, these products do not substitute for employing good sanitation and cultural practices for disease management.

Question 11: Am I eligible for crop insurance for losses incurred growing hemp?

The U.S. Department of Agriculture’s Risk Management Agency (RMA) administers the federal crop insurance program. Crop insurance is available for most agronomic crop and nursery operations, covering production losses due to severe weather and unforeseen circumstances. A pilot hemp insurance program is available in certain states but not Maryland. Maryland hemp growers could be eligible for Whole Farm Revenue protection, with more information available here: https://www.rma.usda.gov/en/Fact-Sheets/National-Fact-Sheets/Whole-Farm-Revenue-Protection.

As RMA works towards national hemp coverage, it is imperative that hemp growers report the hemp acreage produced on their operation to their county Farm Service Agency (FSA) office. Reporting acres is crucial, as RMA will determine a state’s eligibility for coverage based on the production of hemp on a minimum number of acres.

For information regarding reporting acres to FSA and a link to locating your county FSA office, visit: https://www.fsa.usda.gov/news-room/news-releases/2020/usda-reminds-producers-to-complete-crop-acreage-reports. For the most up-to-date information on crop insurance coverage, visit: https://www.rma.usda.gov/en/Topics/Hemp.

Question 12: How do I know when I should harvest my hemp?

To comply with Federal guidelines, growers must harvest industrial hemp before the concentration of THC rises above the legal limit of 0.3%. The Federal Register notice containing the official federal guidelines for hemp production can be found at: https://www.federalregister.gov/documents/2021/01/19/2021-00967/establishment-of-a-domestic-hemp-production-program.

We recommend producers start monitoring the THC concentration of their hemp crop as soon as the plants begin to flower. You should collect plant tissue samples to be analyzed for phytochemical concentration multiple times prior to harvest. Collect a final sample within 30 days prior to harvest. You may request MDA or an authorized agent collect this final sample; see https://mda.maryland.gov/plants-pests/Documents/MD-Hemp-Farming-Regulations.pdf for more information. The sample must prove that the THC concentration of the hemp crop is below the legal limit. Results of this sampling must accompany any hemp sold or transported from the operation to prove the material complies with federal regulations. Any material that has THC concentration above the federal legal limit must be destroyed since it is considered marijuana and possession is illegal.

For more information about how to collect hemp tissue for phytochemical testing, see https://www.regulations.gov/document/AMS-SC-19-0042-0573.

Question 13: After I produce hemp, what do I do with it? Who will buy it from me?

Hemp is unlike other commodity crops, which have different options for selling your grain at the end of the season. If a hemp grower waits until the end of the season to sell their crop, there may not be a buyer available.

In an emerging market, it is extremely important to have a planned buyer for your hemp material before you plant your crop. You should spend time prior to planting investigating potential buyers or processors. Once a buyer is identified, communicate about the expectations for production, including specifications for the material, transportation, and price to be paid. It is important to develop a contract or agreement before planting. More information on developing contracts with hemp buyers can be found at: http://agecon.ca.uky.edu/hemp-contract-considerations.

If you will not be selling your crop immediately, you must plan for appropriate long-term storage of the material. This storage, which must control for temperature and humidity, will add additional equipment and costs to your bottom line.

NICOLE M. FIORELLINO

nfiorell@umd.edu

EMILY ZOBEL

ezobel@umd.edu

KAREN RANE

rane@umd.edu

ANDREW RISTVEY

aristvey@umd.edu

This publication, Industrial Hemp Production in Maryland: Frequently Answered Questions (FS-1172), is a part of a collection produced by the University of Maryland Extension within the College of Agriculture and Natural Resources.

The information presented has met UME peer-review standards, including internal and external technical review. For help accessing this or any UME publication contact: itaccessibility@umd.edu

For more information on this and other topics, visit the University of Maryland Extension website at extension.umd.edu

University programs, activities, and facilities are available to all without regard to race, color, sex, gender identity or expression, sexual orientation, marital status, age, national origin, political affiliation, physical or mental disability, religion, protected veteran status, genetic information, personal appearance, or any other legally protected class.