Proper installation of a wood-fired heating system is crucial for safety and efficiency. Improperly installed wood burners and chimneys are significant fire hazards. Most states have fire code standards for stove installation, typically enforced by local building code officials. Always adhere to the manufacturer’s instructions and state and local building codes, especially regarding clearances from combustible surfaces.

Professional assistance is recommended for selecting and installing a wood-fired heating system. The following guidelines are general and not exhaustive. Refer to your owner’s manual and local building codes for detailed information. When in doubt, consult a professional wood stove installer.

Location: Place your stove in a frequently used, central area like the living room or family room. Ensure the structural support under the floor is adequate. The most efficient location is the center of the room for even heat distribution. Avoid placing the stove in a closet or alcove. Ensure it is safe from combustible surfaces and does not obstruct the home’s traffic flow.

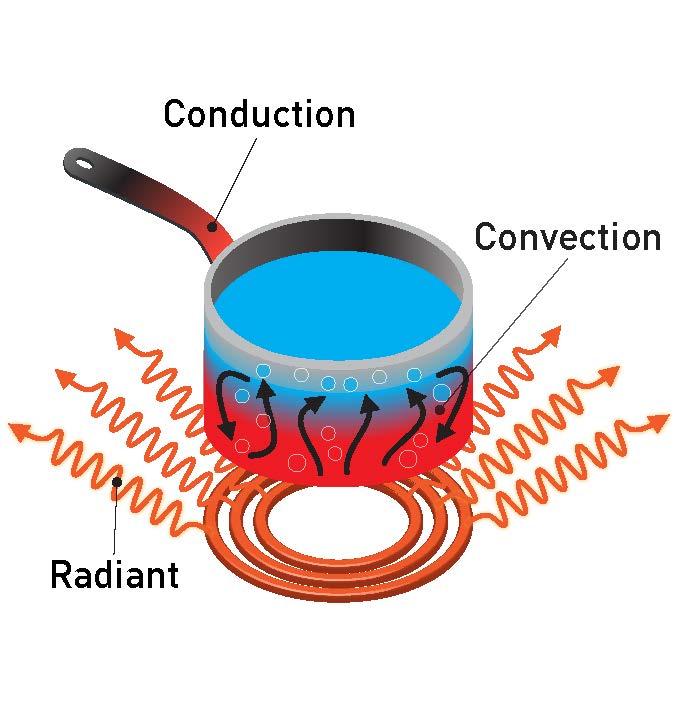

Installation: Maintain proper clearances between the stove and surrounding surfaces to prevent fire hazards. Consider heat transfer from the stove, stovepipe, and chimney.

Clearances from Combustible Materials: Noncombustible materials include steel, iron, brick, tile, concrete, slate, and glass. Walls with wood framing, plaster, and sheetrock are combustible. Prolonged heat exposure lowers the ignition temperature of combustible materials. Ensure adequate clearance from combustible materials like joists, rafters, and wall studs. If unsure, assume walls and ceilings are combustible and maintain proper clearance.

Flooring: Noncombustible floors include concrete, slab-on-grade, or solid concrete with steel or concrete supports. An existing masonry hearth extension is noncombustible if no wood forms are left below it and if there is at least 18 inches of hearth extension in front of the loading door. Wood floors, carpets, and synthetic materials are combustible and must be protected appropriately. Other combustible materials include furniture, draperies, books, and clothing.

All stoves and stovepipes must maintain a minimum clearance from unprotected combustibles on all sides and above the stove. Building codes specify these clearances to prevent overheating and ensure safety. The required clearances can be found on the certification label or in the manufacturer’s installation instructions.

For uncertified stoves, the minimum clearances are substantial: 48 inches for radiant stoves and 36 inches for stoves with convection jackets. If no instructions are available, follow state building codes and use the clearances listed here as a guide. EPA-certified stoves have specified clearances that vary by construction. If a stove lacks a certification label, it is not EPA-certified, and some insurance companies may not cover it. Improper installation can also void your insurance policy in case of a fire.

No clearance is needed for stoves or stovepipes adjacent to noncombustible walls (e.g., concrete), but allowing at least six inches for air circulation and heat dissipation is advisable.

Clearances for Wood Stoves and Stovepipes:

- Follow state and local building codes and manufacturer’s instructions. Use the larger clearance if there is a discrepancy, but never go smaller than recommended.

- Maintain a minimum 36-inch clearance from unprotected combustibles above and on all sides of the stove.

- A single-wall stovepipe requires at least an 18-inch clearance from combustible walls and ceilings, measured at right angles to the pipe.

- The only acceptable base for a stove without special protection is a noncombustible floor or a properly built hearth extension, extending at least 18 inches on all sides of the stove.

Protected Walls and Ceilings

A wood stove and stovepipe can be placed closer than 18 inches to a combustible material if protected by an approved clearance-reduction system. The two common types are:

- 24-gauge sheet metal (galvanized steel, aluminum, or copper)

- 3-1/2-inch-thick masonry wall (4-inch nominal)

Both materials must be spaced one inch from the combustible surface, creating an air gap. For sheet metal, use noncombustible spacers to maintain this gap. For masonry walls, use metal wall ties and furring strips if needed. Ensure the air space is maintained around the entire perimeter to allow heat dissipation and prevent fire hazards. Do not place spacers or wall ties directly behind the stove or stovepipe. Without this air space, the protection is ineffective.

Protective or Clearance-Reduction Systems

A clearance-reduction system creates a ventilated airspace between a heat source and combustible material, spaced one inch from the combustible surface. This reduces heat transfer, allowing for reduced clearances. Prefabricated clearance-reduction systems are available from wood stove and fireplace dealers. Ensure the system is safety-listed and designed for use with a wood stove, and follow the manufacturer’s installation instructions.

The system should be centered behind or above the stove and stovepipe to protect the wall or ceiling. It should extend at least 36 inches past the stove in height and width, measured diagonally. If the stove is placed farther from the wall than the minimum required distance, measure from the stove’s side and top edge to the unprotected wall to determine the system’s dimensions, ensuring at least 36 inches. Larger distances between the stove or stovepipe and the wall require smaller clearance-reduction systems.

Some manufacturers may specify greater clearances. For detailed clearance requirements, contact your local fire marshal’s office.

Floor Protection

All combustible floors must be protected. The only base for a stove without special protection is a noncombustible floor or a properly built hearth extension. Manufacturers of listed stoves usually specify the required floor protection material. If not specified, you can use safety-tested and listed prefabricated stove boards.

Requirements:

- Floor protection should extend at least 18 inches in front of the loading door to prevent damage from sparks, embers, ash, or radiant heat.

- It should also extend 18 inches or more on the remaining sides of listed stoves, unless the manufacturer specifies a greater amount.

- Unlisted stoves require at least 18 inches of floor protection on all sides, including the loading and ash doors.

If multiple stove boards are needed, join them using a safety-tested and listed stove board adapter or a strip of 24-gauge sheet metal, 4 to 6 inches wide.

Stove Leg Length:

- Less than 2 inches: Use floor protection as specified by the manufacturer, safety-tested and listed prefabricated stove boards, or a noncombustible floor.

- 2 inches or greater: You may use a combination of sheet metal and masonry.

Arrangement:

- Legs 2 to 6 inches: Floor protection can consist of 4-inch (nominal) hollow masonry for air circulation, covered with 24-gauge sheet metal. An additional masonry layer can be added for aesthetics.

- Legs higher than 6 inches: Use closely spaced masonry units of brick, concrete, or stone, at least 2 inches thick, covered by or placed over 24-gauge sheet metal.

Ensure each stove leg has a firm, solid footing.

Chimneys and Stovepipes

The chimney is the driving force behind a wood-fired heating system, working in a feedback loop with the stove or fireplace. Heat in the chimney creates a draft, pulling in more combustion air, which makes the fire burn hotter and delivers more heat to the chimney, enhancing the draft further. An insulated chimney generates more draft with less heat.

Chimneys for wood stoves must meet “all fuel” or “Class A” standards and should follow these design guidelines:

- Located inside the heated space rather than on an outside wall.

- Taller than the building.

- Penetrate the building envelope at or near its highest point.

- Straight up, with no elbows or offsets.

- Insulated around the flue liner.

- Flue sized to match the stove.

Chimney height is crucial for proper draft and fire code compliance. The chimney should extend at least three feet above the roof exit point and be at least two feet higher than any part of the roof within ten feet. This is known as the “3-2-10 Rule.”

Stack Effect or “Cold Hearth Syndrome”

When the stove is not in use, a house taller than the chimney can create a stack effect, where warm air rising in the house creates a slight negative pressure at the stove level. If the chimney is shorter than the house, it cannot compete, causing the flow direction in the chimney to reverse and pull cold air and potentially exhaust into the house.

The 3-2-10 Rule

To ensure proper draft, the chimney must extend at least three feet above the roof and be at least two feet higher than any part of the roof within ten feet, measured horizontally. If the chimney is more than ten feet from the roof ridge, use the following formula to calculate the required height:

(roof slope x distance to ridge) + 2 feet = required height above the roof

For example, a chimney on a 5/12-slope roof located six feet from the ridge requires:

(5/12 x 6 ft) + 2 ft = 4 ft, 6 in above the roof

Chimney Connector (Stovepipe)

The chimney connector, commonly known as the stovepipe, links the stove to the chimney. It can be constructed with either a single or double metal wall, with double-wall construction offering better protection and often required by home insurers.

Key Guidelines:

- Prohibited Areas: The stovepipe must not pass through walls, ceilings, attics, closets, or any concealed spaces.

- Fire Safety: Most house fires related to wood heaters originate around the chimney or stovepipe. Causes include creosote buildup, proximity of metal chimneys to combustibles, chimney failure, improper construction or deterioration of masonry chimneys, and incorrect installation of the stovepipe.

Safety Precautions:

- Consult Authorities: Before installation, contact the fire marshal and local building code officials for safety guidelines and inspection requirements.

- Optimal Length: The stovepipe should be as short as possible, with installations up to five feet being acceptable.

- Design Considerations: Aim for a vertical stovepipe with minimal horizontal sections and elbows to ensure the best draft and reduce creosote buildup.

Thimbles:

- Usage: Use a metal or fire clay thimble when passing a stovepipe through noncombustible walls. The thimble should be cemented into the masonry chimney and extend to the inner face or liner without protruding into the chimney.

- Installation: Insert a short section of stovepipe, crimped on both ends, into the thimble and secure it with high-temperature sealant. The stovepipe should extend as far as possible into the thimble without sticking out into the chimney.

Class A Chimney:

- Requirement: For venting through combustible walls, a “Class A” chimney is required. Once the stovepipe connects to the chimney, it must remain a chimney from that point onward, with no further use of stovepipe allowed.

Masonry vs. Metal Chimneys

Choosing between a masonry or metal chimney involves several considerations, each with its own advantages and disadvantages.

Metal Chimneys:

- Cost and Installation: Generally less expensive and easier to install in existing homes.

- Insurance: Some insurance companies may not cover homes with metal chimneys, so check with your insurer before installation.

Masonry Chimneys:

- Construction: Typically require an experienced mason and are often built during the construction of the house.

- Cleanout Opening: Must have a cleanout opening for creosote removal, located more than two feet below the stovepipe entry port, made of ferrous metal, and equipped with an airtight door.

- Chimney Cap: Often added to prevent rain entry, with options ranging from flat steel or concrete plates to more decorative ceramic and metal caps.

- Durability and Aesthetics: Highly durable and often considered more attractive. They also store and release heat longer after the fire has subsided.

- Disadvantages: More expensive to build, harder to inspect and maintain, and less efficient if built on exterior walls due to heat loss and creosote buildup.

Safety Considerations:

- Structural Integrity: Must withstand years of use and occasional chimney fires, with temperatures reaching up to 2,700°F.

- Air and Draft: Ensure the stove has adequate air for combustion and proper draft.

- Condition Check: Inspect for loose bricks and mortar cracks. Have a competent mason repair any issues or add a chimney liner if necessary.

- Compliance: Older chimneys may not meet “all fuel” or “Class A” standards but can be made safe with safety-listed liners.

- Flue Requirements: Each wood-burning appliance must have its own flue. Seal any unused entry ports or breachings with masonry and fire clay mortar to ensure safety.

By considering these factors, you can choose the chimney type that best suits your needs while ensuring safety and efficiency.

Chimney Inspection and Cleaning

Regular inspection and cleaning of chimneys are essential to prevent deterioration and creosote buildup. Even well-built chimneys can settle and require repairs over time, while poorly built chimneys pose immediate dangers.

Inspection Frequency:

- Inspect and clean chimneys at least once a year.

- If using your wood stove daily, inspect and clean as often as biweekly.

- Disassemble and inspect the stovepipe regularly.

Creosote Management:

- Creosote deposits should not exceed one-quarter inch in thickness on the chimney or stovepipe.

- Inspect the flue at both the stove end and chimney top, as cooler surfaces near the top will have the thickest deposits.

Cleaning:

- You can hire a professional or clean the chimney yourself.

- If cleaning yourself, wear protective gear (mask, goggles, gloves) and use a quality steel-bristle brush.

- Clean the inside of the stove and stovepipe as well.

- If you suspect leaks or cracks, have a professional perform a leak test and repair any issues immediately.

Annual Inspection:

- Chimneys passing through attic areas must be inspected annually for cracks.

Combustion Air

State and local building codes may require an outdoor air inlet to ensure adequate combustion air. The size, design, and location of the inlet depend on various factors, such as chimney type and height, and stove heating capacity. Consult your building code officials for specific requirements.

Importance of Outdoor Air Supply:

- Without an outdoor air supply, the stove will draw air from the room, potentially causing dangerous back drafting of gases and smoke.

- Inadequate combustion air can also cause central furnaces or water heaters to backdraft toxic gases.

Design Considerations:

- Some wood stoves draw outdoor air directly into the stove, ensuring adequate combustion air and reducing unwanted infiltration.

- For new homes built to meet energy codes, an air inlet is necessary.

- Proper design is crucial to avoid issues such as back drafting, especially if the intake is on the downwind side of the house during severe weather.