FS-994 | October 2014, Updated July 2024

Anaerobic Digestion: Basic Processes for Biogas

A Biological Process

Anaerobic digestion is a process in which anaerobic bacteria break down or "digest" organic material in the absence of oxygen to produce "biogas" as a by-product of their metabolism. The process occurs naturally in water-logged soils, deep water bodies, and in the digestive systems of termites and large animals (that includes you)¹.

In anaerobic digesters, naturally-occurring biological processes are exploited in an engineered system to treat and dispose of waste materials, stabilize end products, destroy pathogens, and generate biogas, a valuable product (Figure 1). Biogas produced in anaerobic digesters consists of methane (50%– 80%), carbon dioxide (20%–50%), and trace levels of other gases such as hydrogen, carbon monoxide, nitrogen, water vapor, and hydrogen sulfide².

Microbes at Work

Harnessing microbes to work for us is not a new concept. We do it every day in numerous activities from making beer to cleaning oil spills. In each case, the biological needs of the microorganisms must be met to encourage rapid growth. In anaerobic digestion, the biological needs of the organisms include:

- food energy (carbon source) that can be degraded;

- moisture; and

- a hospitable environment in terms of temperature, a lack of oxygen, and a neutral pH.

Microbial Processes

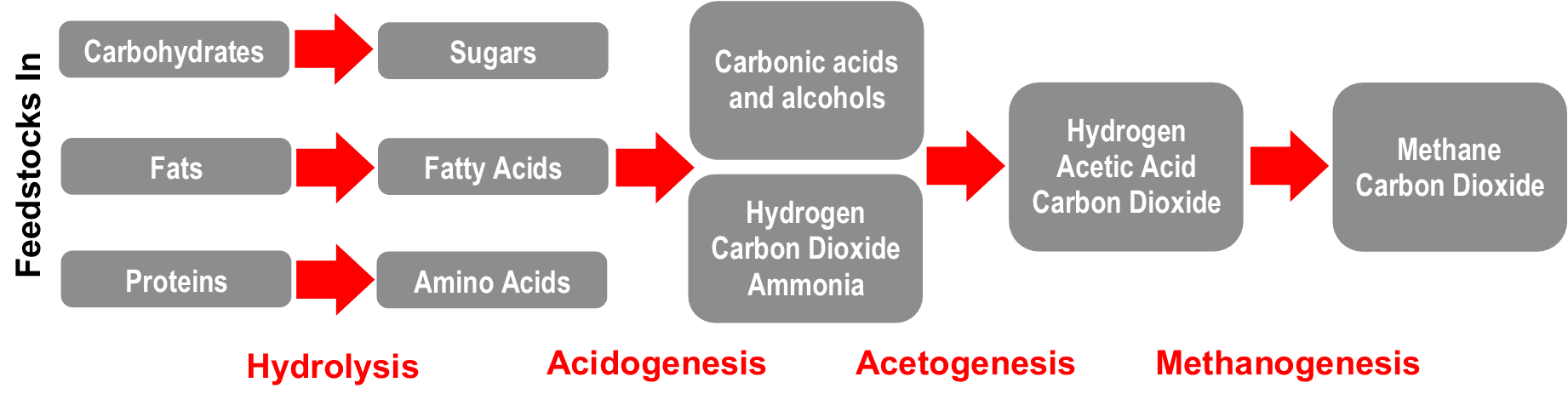

Anaerobic digestion occurs in four processes and is carried out by various groups of bacteria working together. Figure 2 shows a general schematic of the processes involved in producing biogas from raw organic feedstocks. The basic processes are described below.

Hydrolysis (or liquification): Microbial breakdown of the input feedstocks (such as corn, grain, sawdust, food waste, or manure) results in simple sugars, fatty acids, and amino acids, which are then available to other bacteria.

Acidogenesis: Bacteria transform the products of hydrolysis into short chain volatile acids, ketones, alcohols, hydrogen, and carbon dioxide.

Methanogenesis: Methane-producing microbes utilize acetic acid, hydrogen, and carbon dioxide to methane.

While we discuss the process in steps, in reality, all of these steps are occurring simultaneously, with different groups of bacteria working together to transform biomass into biogas.

Additional groups of bacteria reduce the hydrogen toxicity by converting hydrogen into ammonia, hydrogen sulfide, and methane⁵. A majority of the bacteria involved in the process are facultative anaerobes, which means they can survive in the presence of oxygen but do not use it. Methanogens, are obligate anaerobes, which means they can only live and grow in the absence of oxygen. The stages of anaerobic digestion function in a dynamic equilibrium whereby if one reaction is inhibited, it will hinder the subsequent reactions⁶.

Digester Types

There are two general classifications of digesters based on the flow through the digester vessel.

Plug-flow digester: A plug flow digester vessel is a long, narrow, insulated, and possibly heated vessel made of reinforced concrete, steel or fiberglass with a gas-tight cover to capture the biogas. The plug flow digester normally functions without internal agitation. This type of digester works well with a scrape manure management system with little bedding and no sand. In theory, the daily input of manure in a plug flow digester functions as a daily plug, advancing towards the outlet whenever new manure is subsequently added. In reality, the manure may not remain as a plug and more liquid components of the manure may flow through the digester at a faster rate with some settling or floating of some solids within the digester.

Complete-mix digester: A complete-mix digesters is typically an above- or below-ground tank that is part of a manure management system to handle manure containing 2 to 10 percent solids. The digester is mixed mechanically or with gas injection to keep the solids suspended. This maximizes biological activity for digestion of volatile solids, methane production and odor reduction.

Biogas from either type of digester can be used to run an engine generator set to produce electrical power. When using a combined heat and power generator, waste heat from the engine may be used to heat the digester.

A Little Bit About Microbes and Their Environment

Temperature

Anaerobic digestion can occur in three different temperature ranges, with the most reactors using the second and third ranges:

- psychrophilic (41-68°F)⁷,⁸

- mesophilic (77-95°F), and

- thermophilic (122-140°F) conditions⁴.

Bacteria, and thus biogas production, may be inhibited at temperatures between 104-122°F⁴. The microbial communities present in one temperature range are not the same as the ones occurring in another temperature range, and thus decreases in biogas production might occur when temperature ranges are not maintained⁹. In general, for optimal biogas production, the anaerobic digester should be kept at a constant temperature¹⁰. In most areas of the United States, anaerobic digesters require insulation, heating, or a combination of both.

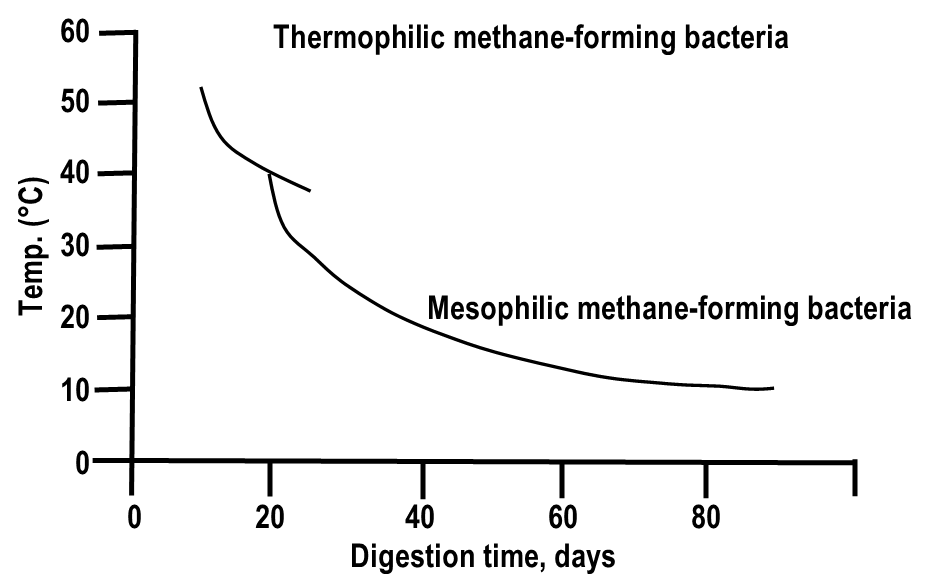

Typically, digesters operated in the mesophilic range are larger than those operated in the higher temperatures of the thermophilic range because the decomposition process takes more time in the lower temperature regime (Figure 3). The mesophilic process is less sensitive to upset or change in operating regimen compared to thermophilic digesters, which have shorter retention times than those operated in the mesophilic range but tend to be more sensitive to changes in feed materials or temperature¹.

pH and Alkalinity

In addition to temperature, pH and alkalinity affect the anaerobic digestion process. Alkalinity is necessary for pH control and acts as a buffer against acid formation during acidogenesis. Methane-producing bacteria (methanogens) are sensitive to pH change and operate optimally between a pH of 6.8 and 7.2⁴. The production and consumption of volatile acids and the carbon dioxide content in the biogas affect the pH⁴. Decreases in alkalinity can occur when organic acids accumulate in the digester due to failure to convert the acids into methane during methanogensis or the introduction of large quantities of organic acids through the digester feed source⁴. A pH buffer, such as sodium bicarbonate, can be added to maintain a consistent pH, or co-digestion with a substance with a high buffering capacity, such as dairy manure, can be used to buffer pH changes from adding substances with higher organic loadings, such as food waste.

Additional Environmental Considerations

Final environmental considerations include the water/solids ratio, carbon/nitrogen ratio, agitation in the digester, particle size of the material, and retention time. It may be necessary to add water to the feed material if it is too dry or if the nitrogen content is high. A carbon/nitrogen ratio of 20:1 to 30:1 is preferred.

Occasional mixing or agitation of the digesting material can aid the digestion process. High levels of antibiotics in the livestock feed could inhibit the anaerobic bacteria in digesters.

Digester Inputs and Outputs

The nitrogen in manure enters the digester mostly in the forms of ammonium and organic nitrogen. In the digester, organic nitrogen is converted to ammonium. Therefore, the effluent will have higher levels of ammonium than the influent manure but similar total nitrogen levels (organic nitrogen + ammonium). If field-applied, the ammonium is available to volatilize if the material is not incorporated into the soil. However, because of the lower solids content, digester effluent will infiltrate better than the raw pre-digestion waste stream, resulting in less volatilization with digester effluent compared to un-digested manure application.

The main difference between the fertilizer value of anaerobically digested waste and either undigested or aerobically digested waste lies in the form of ammonia (NH³) or, more precisely, the ammonium ion (NH⁴⁺). In aerobic oxidation, nitrogen is oxidized to form nitrates and nitrites. For fertilizer application, ammonium may be a more appropriate source of nitrogen than either nitrates or nitrites. Ammonium is less likely to leach away and more apt to become fixed to the negatively charged particles (clay and humus) in soil.

Phosphorus may precipitate in the digester. A portion of this precipitate may settle in the solids of the digester and measurement at the outlet might give the impression that the mass of phosphorus is reduced by the digester. However, when the digester is cleaned, as is periodically necessary, the precipitated phosphorus will “re-appear”. There is no real loss of phosphorus in the digester.

The solids content entering an anaerobic digester can range from 7% to 13%. Once digested, the slurry becomes more of a soupy mixture composed of more fine solids suspended in the liquid. This composition makes it possible to use the waste as a liquid (agitating may be necessary) or to further liquefy the effluent leaving the digester by separating the solids and using these solids as bedding in the dairy barn or selling as compost material. The remaining liquid can then still be applied to the fields as an agricultural fertilizer.

In a plug flow digester, the conversion efficiency of volatile solids to biogas can approximate 70%, making it more efficient than many other energy conversions. However, when electrical generation is added into the system, and the biogas is not used directly for heating purposes, the system efficiency can decrease to approximately 20%-30%, as the engine generator set converting the methane in the biogas to electricity has efficiencies of 25-40%.

In our temperate climate, the anaerobic digester is only slightly exothermic, meaning the heat released by the microorganisms through their metabolic processes is not large, and therefore, the digester will need extremely good insulation, additional heat, or a combination to maintain a mesophilic or thermophilic temperature in the winter and function efficiently. It has been estimated that approximately up to one third of the energy contained in the biomass may be necessary to keep the digester sufficiently heated to function efficiently during the winter.

Benefits of the Process

The utilization of anaerobic digesters results in multiple environmental and economic benefits.

These include:

- production of renewable energy;

- reductions in odor;

- reductions in greenhouse gas emissions;

- improved water quality; and

- reductions in viable weed seeds.

Energy

Anaerobic digestion produces energy that can be used for heating or generating electricity, both of which change waste management expenses into an income generating enterprise.

Odor

The effluent and gas (when combusted and utilized) is almost odor-free¹⁵,¹⁶. In these times of encroaching urbanization, that is a major advantage of farm-based digesters and is the sole purpose for some installations.

Greenhouse Gas

Because the methane is consumed to produce energy, the high greenhouse gas (GHG) impact from methane being released into the atmosphere from traditional manure management (i.e. lagoons) is greatly diminished (methane has 21 times the global warming potential of carbon dioxide)¹⁹.

In a life-cycle assessment (LCA), a conventional manure handling system had almost five times the greenhouse gas impact as an anaerobic digestion system. Because the methane is combusted to produce heat, the greenhouse gas (GHG) impact from methane is greatly diminished when the methane is utilized (combusted in a generator or directly for heat/cooking). Anaerobic digestion provides an energy source with no net increase in atmospheric carbon. Additionally, the need for fossil fuel is displaced and the economic burden from purchasing fossil fuel is decreased²¹.

Water Quality

Solids are reduced by 50-90%. Reduced solids translate into reduced biochemical oxygen demand (the amount of dissolved oxygen needed by aerobic biological organisms in the water to break down organic material), which improves the downstream water quality¹¹.

Other

Escherichia coli O157:H7, Salmonella, Cryptosporidium and other pathogens are found in manure and are potentially harmful to humans. An anaerobic digester has a pathogen-reducing effect with over a 90% reduction of the pathogens introduced in the manure influent¹¹,¹²,¹³. Higher rates of pathogen reduction are achieved with thermophilic digestion¹⁴.

Because the odor is essentially eliminated, flies will not be drawn to the effluent and the fly population will drop. Anaerobic digestion has also been shown to destroy weed seeds, so digested slurry can be used without fear of weed infestation¹⁷,¹⁸.

Uses of Biogas

- Methane gas can be used directly as a replacement for natural gas. It can be used in radiant heating, directly for cooking, lighting, as a transportation fuel, or other applications where natural gas is utilized. Because the energy content is lower in biogas (500-800 BTU/ft³) compared to natural gas (1,000 BTU/ft³), a larger quantity of biogas is needed when used directly or compressed for use as a vehicle fuel or in a natural gas generator. The greater quantity of biogas requires a larger volume or storage vessel.

- Biogas can be used in an engine generator set to create electricity. The engine generator uses the methane in the biogas and combusts the methane, which drives the turning of a shaft through a magnet to create electricity – the same way electricity is generated in a natural gas generator. Excess heat from a combined heat and power generator can be used to heat the digester and provide other heating needs on-farm.

- The carbon dioxide in the biogas can be removed, often at a great expense, to upgrade the biogas to natural gas quality (97-99% methane) and use in traditional natural gas infrastructure (pipelines, vehicles, generators).

More Information:

For more information on animal waste technologies and anaerobic digestion, please visit https://go.umd.edu/AWTF.

Additional contacts:

- Dr. Stephanie Lansing (UMD): slansing@umd.edu

- Dr. Gary Felton (UMD): gfelton@umd.edu

References:

- Dept of Energy (DOE) Energy Efficiency & Renewable Energy. Anaerobic Digestion. (2013).

- Dept of Energy (DOE) Alternative Fuels Data Center. Renewable Natural Gas (Biogas). (2013).

- Sullivan, D. Anaerobic Digestion in the Northwest. Biocycle 53(3): 33. (2012).

- Gerardi, M.H. The Microbiology of Anaerobic Digesters. J Wiley & Sons; Hoboken, NJ. (2003).

- Burke, D.A. Dairy Waste Anaerobic Digestion Handbook. Environmental Energy Company, Olympia, WA. (2001).

- Wilkie, A.C. Anaerobic Digestion: Holistic Bioprocessing of Animal Manures. Animal Residuals Management Conference, Alexandria, VA, 1-12. (2000).

- Lettinga, G., Rebac, S., Parshina, S., Nozhevnikova, A., van Lier, J.B., Stams, A.J.M. High-rate anaerobic treatment of wastewater at low temperatures. Appl Env Microbiol, 65: 1696-1702. (1999).

- Masse, D.I., Croteau, F., Masse, L. The fate of crop nutrients during digestion of swine manure in psychrophilic anaerobic sequencing batch reactors. Bioresource Tech, 98: 2819-23. (2007).

- Ward, A.J., Hobbs, P.J., Holliman, P.J., Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresource Tech 9: ,7928-40. (2008).

- Chae, K.J., Jang, A., Yim. S.K., Kim,I.S. The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresource Tech 99: 1-6. (2008).

- Lansing, S., Viquez, J., Martinez, H., Botero, R., Martin, J. Quantifying electricity generation and waste transformations in a low-cost, plug-flow anaerobic digestion system. Ecol Eng 34: 332-48. (2008).

- Lusk, P. Methane Recovery from Animal Manures the Current Opportunities Casebook. NREL/SR-580-25145, National Renewable Energy Laboratory, Golden, CO. (1998).

- Olsen, J.E. and H.E. Larsen, 1987. Bacterial Decimation Times in Anaerobic Digestions of Animal Slurries. Biol Wastes, 21: 153-68. (1987).

- Topper, P.A. and R.E. Graves. The fate of nutrients and pathogens during anaerobic digestion of dairy manure. Fact Sheet G71. Penn State University, State College, PA. (2006).

- Powers, W.J., Van Horn, H.H., Wilkie, A.C., Wilcox, C.J., Nordstedt, R.A. Effects of anaerobic digestion and additives to effluent or cattle feed on odor and odorant concentrations. Journal of Animal Science, 77: 1412-21. (1999).

- Wilkie, A.C. Reducing dairy manure odor and producing energy. Biocycle, 41:48-50. (2000).

- Eckford, R.E., Newman, J.C., Li, X., Watson, P.R. Thermophilic anaerobic digestion of cattle manure reduces seed viability for four weed species. Int J Agric & Biol Eng 5(1): 71-5. (2012).

- Westerman, P.R., Heiermann, M., Pottberg, U., Rodemann, B., Gerowitt, B. Weed seed survival during mesophilic anaerobic digestion in biogas plants. Weed Research 52: 307-16. (2012).

- Calander, B. Scientific Aspects of the Framework Convention on Climate Change and National Greenhouse Inventories. Env Monitoring Assessment, 38:129-40. (1995).

- Clarke Energy. Biogas. www.clarke-energy.com/applications/biogas. Accessed 7/9/2024. (2024).

GARY FELTON

gfelton@umd.edu

STEPHANIE LANSING

slansing@umd.edu

ANDREW MOSS

KATHERINE KLAVON

This publication, Anaerobic Digestion: Basic Processes for Biogas (FS-994), is a part of a collection produced by the University of Maryland Extension within the College of Agriculture and Natural Resources.

The information presented has met UME peer-review standards, including internal and external technical review. For help accessing this or any UME publication contact: itaccessibility@umd.edu

For more information on this and other topics, visit the University of Maryland Extension website at extension.umd.edu

University programs, activities, and facilities are available to all without regard to race, color, sex, gender identity or expression, sexual orientation, marital status, age, national origin, political affiliation, physical or mental disability, religion, protected veteran status, genetic information, personal appearance, or any other legally protected class.

When citing this publication, please use the suggested format below:

Felton, G., Lansing, S., Moss, A., & Klavon, K. (2014, updated 2024). Anaerobic

Digestion: Basic Process for Biogas (FS-994). University of Maryland Extension.

go.umd.edu/FS-994.